What is Value Engineering?

Value engineering is defined by The General Services Administration as:

“An organised effort directed at analysing designed building features, systems, equipment and material selections with the purpose of achieving essential functions at the lowest life cycle cost consistent with required performance, quality, reliability and safety”.

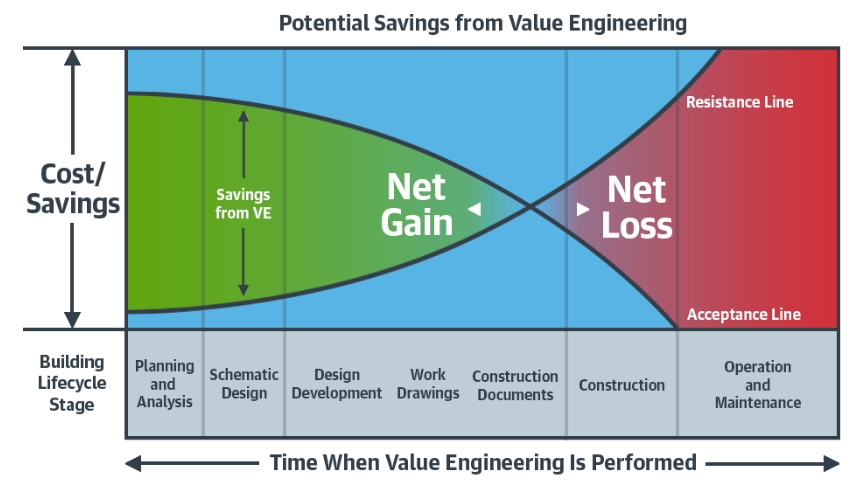

Value engineering takes place in the design phase of building development to consider alternative design solutions which will “optimize the expected cost/worth ratio of a project at completion”.

How is value engineering calculated?

Value is calculated as a ratio of function to cost. This means you can add value to a project by reducing costs or improving functionality – ideally both at the same time. Value engineering should never compromise the quality of a project, only save time and money where possible.

What is involved in value engineering?

Value engineering involves the following phases:

- The information/identification phase

This stage requires information gathering to understand the project and the design. Here you will analyse the forecast of all spending and processes related to the project to work out the priorities of the project and areas of improvement.

To do this all costs of the project must be broken down, from materials to the way the materials are delivered. Once all the costs have been analysed it will be clear where the largest costs lie and where you should focus value engineering activities.

- The function analysis phase

This phase involves defining each function of a project which will set targets to be achieved through the execution of a project. This allows for multiple options to be identified which will perform the function. A cost can be allocated to each function which helps to narrow down viable options.

- The creative phase

Here all the findings from phases 1 and 2 should be collectively analysed by your team via a brainstorming session to uncover possible solutions. From these discussions, you should create a list of potential solutions such as changing the project design, removing redundant features or changing the materials used.

Some useful questions to consider include: What is the task? What does it cost? What does it do? Why is it required? What is it worth? What else could achieve the same result?

- The evaluation phase

This phase involves looking over the suggested solutions in phases 2 and 3 and giving the pros and cons. Here you’ll need your team to present their ideas and deliberate potential solutions. It is important to note that multiple advantages may not outweigh a large disadvantage which could impact the whole project.

- The analysis and development phase

During this phase, the best ideas should be taken further and analysed to reveal true consequences. This may include producing revised financial projections and assessing the overall viability of the proposed changes. Here the team should create an implementation plan for the project with the revised recommendations.

- The presentation phase

This phase requires the final report to be presented with the key facts, changes and potential issues. The whole point of value engineering is to enhance the value of the project and so this should be the underlying point of the presentation from start to finish.

Here it is useful to include:

- Timelines

- Financial projections

- Drawings

- Risks

- Benefits

There are bound to be a lot of questions asked during this phase which may result in further changes being made. In the end, there could be multiple changes made to the project which will need to be implemented.

Important tip: If a company lack the expertise to brainstorm appropriate changes, it may wish to involve a third party to manage these phases, handing back over to the company after the presentation to decide which changes they wish to make.

How is value engineering helpful?

Value engineering allows companies to reconsider alternatives – This could potentially save a lot of money in the long run and allow for changes to be considered before going ahead with a large project.

Value engineering saves money – This is arguably the biggest benefit of value engineering as it can really reduce the expenses associated with a project. For example, simply substituting one material or one manufacturer has the possibility to save you thousands of pounds which can be used for other elements of the project.

Reduce waste – Value engineering will look at the whole project to find ways to reduce waste where possible. This includes wasted materials, wasted labour and wasted time.

Keep the project on schedule – Value engineering can actually speed a project up by making it more efficient. Even with proposed changes, value engineering always aims to meet the delivery date of a project.

What are the types of value?

- Use value: This looks at the overall use of each aspect of a construction project and ensures that it achieves the desired use.

- Cost value: This is self-explanatory and simply asks if the cost is worth the value it brings.

When should value engineering take place?

Traditionally, value engineering should happen during the design phase of a construction project. However, this is not essential. Value engineering can still take place in the construction phase if a project is costing a lot more than predicted or if the project manager is facing challenges which need to be addressed.

Thanks for sharing. I read many of your blog posts, cool, your blog is very good.

I am a website designer. Recently, I am designing a website template about gate.io. The boss’s requirements are very strange, which makes me very difficult. I have consulted many websites, and later I discovered your blog, which is the style I hope to need. thank you very much. Would you allow me to use your blog style as a reference? thank you!

I don’t think the title of your enticle matches the content lol. Just kidding, mainly because I had some doubts after reading the enticle. https://www.binance.com/en/register?ref=P9L9FQKY

I may need your help. I’ve been doing research on gate io recently, and I’ve tried a lot of different things. Later, I read your article, and I think your way of writing has given me some innovative ideas, thank you very much.

I may need your help. I’ve been doing research on gate io recently, and I’ve tried a lot of different things. Later, I read your article, and I think your way of writing has given me some innovative ideas, thank you very much.

The point of view of your article has taught me a lot, and I already know how to improve the paper on gate.oi, thank you. https://www.gate.io/ru/signup/XwNAU

I have read your article carefully and I agree with you very much. This has provided a great help for my thesis writing, and I will seriously improve it. However, I don’t know much about a certain place. Can you help me? https://www.gate.io/uk/signup/XwNAU

The point of view of your article has taught me a lot, and I already know how to improve the paper on gate.oi, thank you. https://www.gate.io/tr/signup/XwNAU

Your article helped me a lot, is there any more related content? Thanks! https://accounts.binance.com/de-CH/register-person?ref=B4EPR6J0

Your article helped me a lot, is there any more related content? Thanks! https://accounts.binance.com/cs/register-person?ref=S5H7X3LP

Can you be more specific about the content of your article? After reading it, I still have some doubts. Hope you can help me. https://www.binance.com/id/register?ref=DB40ITMB

Your article helped me a lot, is there any more related content? Thanks! https://accounts.binance.com/lv/register-person?ref=B4EPR6J0

Your article helped me a lot, is there any more related content? Thanks! https://accounts.binance.com/sv/register-person?ref=DB40ITMB

Your point of view caught my eye and was very interesting. Thanks. I have a question for you. https://accounts.binance.com/vi/register?ref=B4EPR6J0

Of course, how can we help?